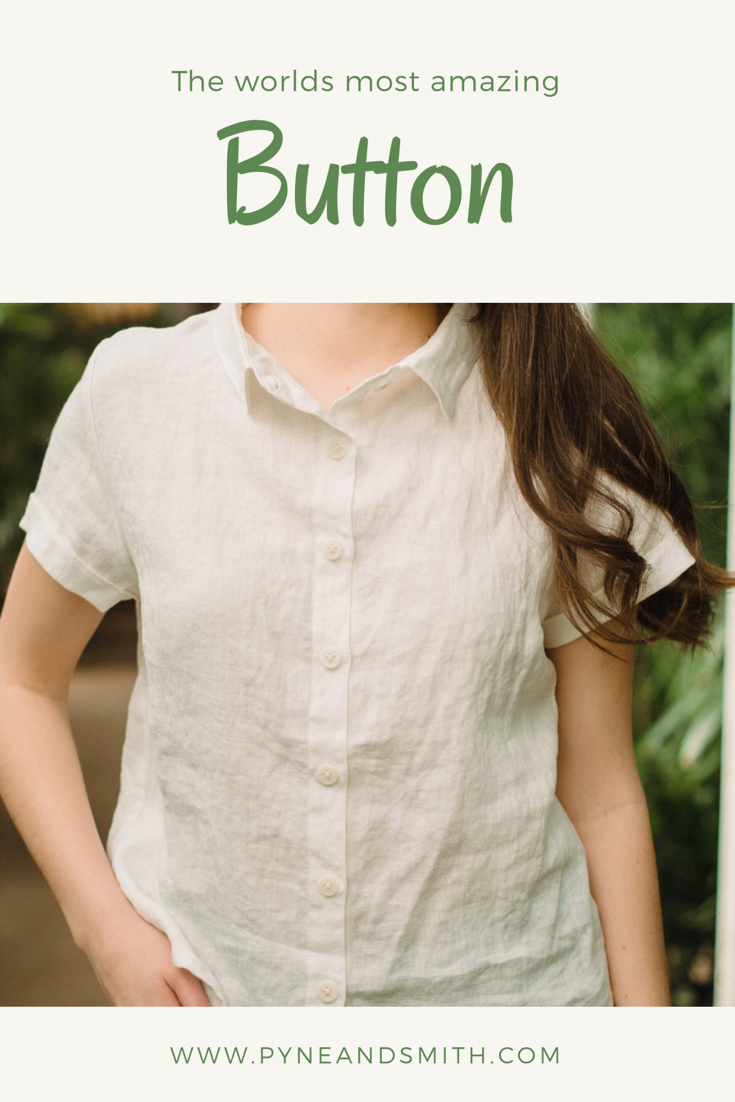

Some new changes for Pyne & Smith in 2018, among others, was our buttons. After trying to find a sustainable, ethically made wooden button, along the way we discovered corozo nut buttons. The quality and story behind this material is more than worth the cost per button, which is significantly more than wooden buttons. Almost identical to the classic P&S wooden button in shape and style, we soon learned that we had every reason to make the switch from wood to the corozo nut button. Sustainably sourced from Central and South America, the corozo nut is not cut down from the tree, instead, they wait for the nut clusters to drop to the ground from the corozo, or Tagua palm tree. The nuts are then dried for three months, once they have become hard and ready to craft. The large nut is then then cut into slices, shaped and dyed to make our beautiful, all natural buttons, per our design! These buttons, once popular in the 1800's and replaced by plastics in the 20th century, were are also known as vegetable ivory for their depth of color and similarity to white ivory before dying. Ethically made - the workers that harvest and craft the corozo are paid a fair, livable wage. No trees are harmed to make these beautiful buttons, in fact, because of the value of the produce of these trees, more are being planted each year. After months of research into finding this forgotten material and working directly with the makers on designs, we're very excited to be finally able to add them to our dresses. They really make a perfect accompaniment to our linen garments!

Additionally, the past 18 months has been spent working almost non stop on finding a garment sewing facility locally, where we could send a larger volume of dresses to be sewn once our quantity became too large for me and my seamstresses to handle. This has been incredibly educational, there are many garment sewing production facilities in Los Angeles, but few of them had working conditions that we were happy supporting. After many visits, sample dresses made and learning lessons, we finally found and began working with a sewing production facility that we were delighted to find, and have been so happy with the garment quality (it really is impeccable) but also the seamstresses and staff are paid a livable wage, and the working conditions are immaculate. Light, bright, happy and clean, with lunch brought in, and a vibrant buzz wherever we stop by to visit.

Lastly, waste. The garment industry is a huge polluter to our planet. We don't want to be a part of that, and even though production waste will happen with making a line of clothing, we are lucky enough to live in a county that offers textile recycling. Specifically, our linen waste scraps are sent to a facility that shreds the linen, then repurposes it into car and airline seat covers. Larger scraps I donate to crafters & quilters.

White Corozo buttons on the linen collared blouse - these white corozo buttons are also know as Green ivory, due to their sustainable harvesting and production process, with a very similar aesthetic to ivory.